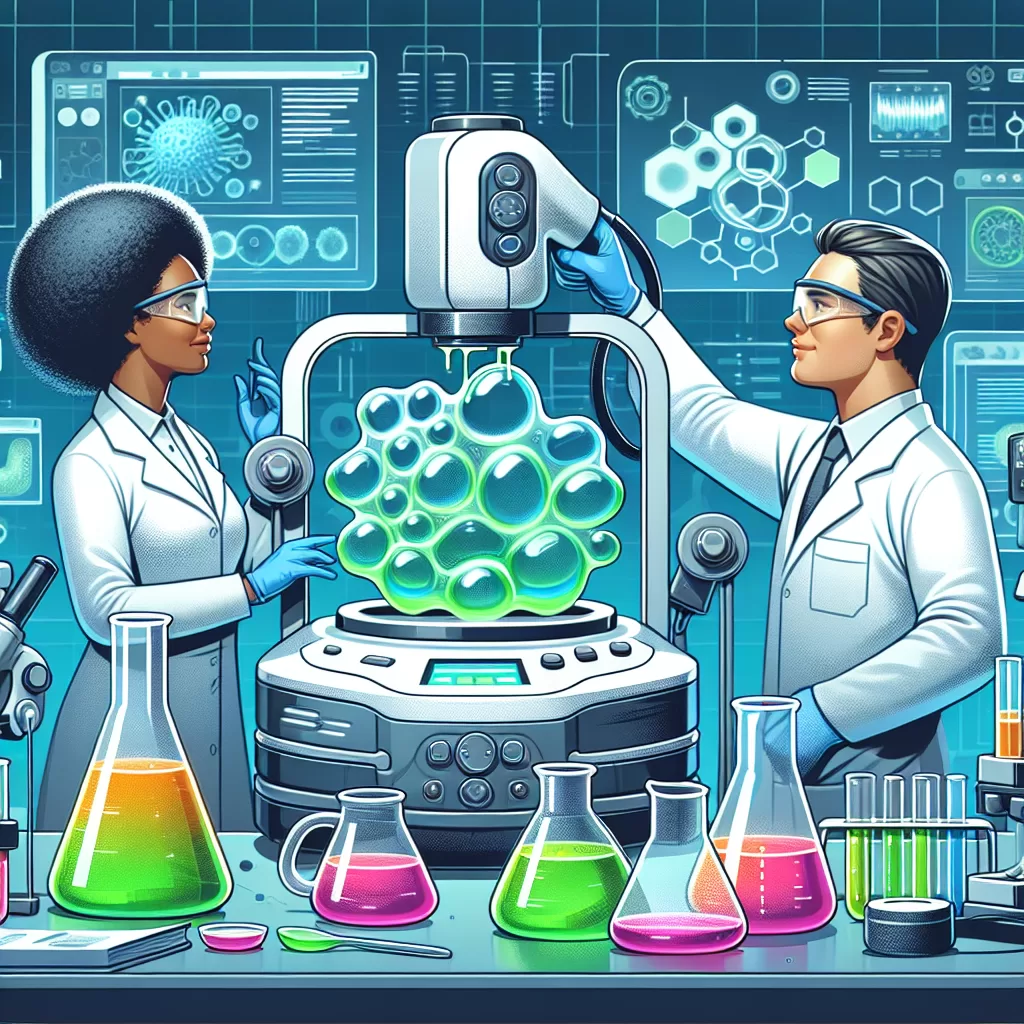

Scientists have unveiled a groundbreaking technique for manufacturing hydrogels using ultrasound technology, paving the way for a more environmentally friendly and efficient production process. This innovative approach eliminates the need for harmful chemical initiators, which have traditionally plagued hydrogel fabrication methods.The novel ultrasound-based method not only offers a faster and cleaner alternative but also yields hydrogels with remarkable properties. These hydrogels exhibit superior strength, enhanced flexibility, and an impressive resistance to freezing and dehydration, making them highly versatile for a wide range of applications.

Notably, this breakthrough holds immense potential for advancing tissue engineering, bioadhesive development, and 3D bioprinting technologies. By providing a safer and more sustainable means of hydrogel production, researchers can accelerate progress in these critical fields while minimizing environmental impact.

As scientists continue to explore the vast possibilities of this ultrasound-driven approach, it promises to revolutionize the way we create and utilize hydrogels, aligning with global sustainability goals and promoting responsible manufacturing practices.